West Bromwich packagers Diamond Box on the up

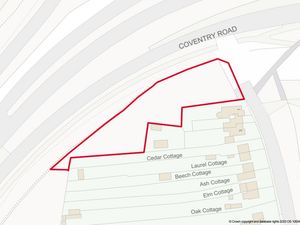

[gallery]Only established in 2007, fast-growing British packaging manufacturer Diamond Box operates from a modern 100,000 sq ft plant in West Bromwich, turning over some £22 million a year.

The site, on the north west side of Birmingham, Diamond Box is ideally positioned close to the centre of the UK's motorway network, and last year the plant converted 50 million square metres of board, putting it right at the top in terms of independent sheet plant output – but there is even more to come.

The company is rapidly establishing itself as one of the UK's premier manufacturers of cardboard boxes, and has made significant investments in modern equipment, infrastructure and staffing to meet the changing demand of the industry.

From its West Bromwich headquarters it services an extensive customer base across the UK with a wide range of corrugated box products.

Constant improvements in service levels, driven by a committed and experienced staff, help the company maintain customer loyalty, in particular by tailoring its business to meet clients' needs.

With expansion very much in mind, Diamond Box has appointed Shaun Watkins as sales director, a new position within the fast growing company.

Shaun joins with a sales growth agenda designed to enable the company to meet a target of £30 million turnover by 2013.

Kavi Jundu, chief executive of Diamond Box, said: "Until now, driving sales forward has been a role split between myself and our sales team.

"The phenomenal growth we have achieved over the past four years means that we now need a dedicated sales director to keep the momentum up and to service our customers in the way they expect."

Shaun has a wealth of experience within the industry and he is just the man to drive sales forward and to look after our key accounts."

Shaun Watkins is a veteran in corrugated sales, including time spent with Saica and, most recently, as regional business manager at Macfarlane Group.

Shaun said: "I'm excited to be joining Diamond Box because it's a business that is going places. With all the consolidation going on in the industry it is the right time for independents who can offer great quality and great service.

"Diamond Box do just that because they invest as and when they need to and they don't suffer from the bureaucracy and lack of flexibility of the corporate."

In the last year Diamond Box has invested in a new Bobst die-cutter and folder-gluer lines, upgraded its waste extraction and materials handling lines, brought in shop floor data collection and installed a new CAD system.

Kavi Jundu said: "As well as investing in equipment and infrastructure, we are also investing in people who can take the business forward.

Shaun is a case in point, as is Tony Arnell, the Starpack award-winning designer we recruited last year. We expect to make other key appointments over the summer that will continue to keep us on track to meet our growth targets."

Diamond Box is proud to be a local business employing local people and is now looking to grow with local business create more employment and expand the local economy Diamond box is the perfect packaging partner for local business.

Keen to break into the market for online vendor packaging, UK-based Diamond Box has chosen a Bobst Visionfold as the manufacturing force behind its new packaging designs.

Kavi Jundu, chief executive of the fast-growing British packaging manufacturer, said: "With hindsight it was a great decision to install the Bobst Visionfold.

"We liked the machine from the first look. We liked its design, we liked its capabilities and we liked the benefits it can bring in terms of run speeds and, very importantly, set up times.

"But the main thing we liked was that it could give us the ability to manufacture the innovative packaging we wanted to create – and do it very cost-effectively."

Having established itself with products from brown box to shelf-ready packaging over the short time since its establishment, the company has now homed in on the fast-expanding online shopping ,arket as one where there were opportunities to be exploited.

"Almost every online sale means mailing pack of some sort has to be used," said Kavi. "Up until now there have only been a few people able to produce them as well. We felt that with the Visionfold we could produce that sort of work very efficiently and at the same time offer packaging buyers something new in terms of design."

Kavi said that Diamond Box's aim with the new Bobst folder-gluer was to deliver packages that offered new functionality, attracted attention or took out costs.

"With the Visionfold up and running we believe we are now the most competitive supplier when it comes to producing packs for the online market.

"Since we have had the machine in full production. Our set up times in gluing have halved and we are running twice as fast as we were.

"The productivity boost has been so great that we have already got rid of our Jagenberg, which we had intended to keep as a part-time machine for simple work. The Visionfold has done everything we thought it would do and more."

The increased productivity that Diamond Box has seen thanks to the Visionfold has meant that the company needed to invest in improved strapping equipment at the end of the line.

"Our old strapper was fine for keeping up woth the Jagenberg, but it couldn't cope with the output of the Bobst," explained operations director Martyn Jones.

"So we have just added a Mosca twin head strapper. The Visionfold is so quick at delivering bundles our fo the back that you need something which can keep up with it.

"The whole model here at Diamond Box is about maximum efficiency – getting the out as quickly as possible. We had an unexpected bottleneck and now we've cured it."

On the back of investing in the Bobst machine, the company has also recruited a Starpack award-winning designer to head up its design team.

"We thought that with a really innovative machine like the Visionfold coming in we should complement it by having access to really innovative design ideas," said company director Rani Jundu.

"That way we can maximise the added value of the machine."

Tony Arnell joined Diamond Box from a successful career with major corporate corrugated packaging manufacturers.

"Tony is winning us work already, thanks to the designs he has come up with that we have never been able to offer before. His knowledge, vision and flair for design, allied to the capabilities of the Visionfold, are really beginning to add value to what we offer – whether it's retail packaging or mailing packs for online shops.

"Certainly our customers are already starting to reap the benefits and people are starting to realise that they can come to us if they want something really design driven and innovative as wellas when theyneed packaging that delivers value engineering, takes cost out or reduces material use."

The plan at Diamond Box is to continue to invest in design, both in terms of people and in the equipment that will manufacture the design team's creations.

"We see our design facility growing under Tony as the company grows," said Rani. "We'll continue to invest in people and their skills. Our aim is to be recognised as having one of the best design departments in the industry."