Cranking it up for motor industry

A 90-year-old Black Country crankshaft business is leading the world after developing a brand new high-strength cast iron material.

Major car companies are now beating a path to Darcast's doors in Smethwick and the company is even exporting to China.

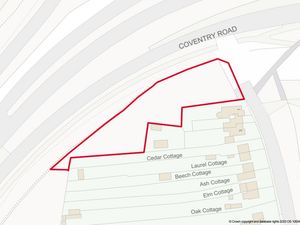

Over the past five years more than £15 million has been spent on rebuilding the Darcast factory, in Cornwall Road, Smethwick, including a £5.5 million project to install four huge new eight mega-watt electric melting furnaces capable of handling 100,000 tonnes of metal a year.

Turnover will hit around £17 million this year and managing director Leonard Bransby is confident that figure will grow further next year. So much work is now coming in that Darcast management will have to consider introducing a second shift - if the current growth continues.

A major element of the growth has been from crankshafts manufactured in the new cast iron, developed after a £1 million research and development programme at the factory's purpose-built laboratory facilities.

Traditionally cast iron crankshafts have not been as strong as forged steel crankshafts, although they are cheaper. Mr Bransby says the tough new cast iron material enables Darcast to produce a cast crankshaft that rivals the strength of forged crankshafts, but at around half the cost.

Darcast can trace its roots back to the old Dartmouth Auto Castings business, founded in 1915, but the recent developments were sparked by a management buyout in April 2004, led by Mr Bransby, which saw the company become an independent business after 14 years as part of German steel giant ThyssenKrupp.

"We needed some way to distinguish ourselves from all the other crankshaft businesses," said Mr Bransby. "We decided to invest in developing a new material that would give us a competitive advantage.

"We developed a differentiation strategy where, rather than attempt to compete purely on price, which is difficult when you face competition from low wage economies, we chose to develop a unique high strength material that would set us apart from our competion. We utilised the experience and knowledge that we have gained during the last 60 years of manufacturing crankshafts."

As the UK's biggest manufacturer of cast crankshafts, Darcast supplies the VW Audi group, including SEAT and Skoda, as well as Toyota, Jaguar and a range of agricultural and construction vehicle manufacturers including JCB and John Deere.

Successful tests of the new material by Audi have led to orders to supply it for use in the company's new worldwide 1.8 litre engine, including exporting crankshafts to the Audi factories in Europe and China.

Initial orders of 60,000 to 70,000 a year from China are expected to grow to 500,000 a year in the next two years. At the moment Darcast makes around 1.5 million cast crankshafts every year - exporting 70 per cent of them - but even bigger orders could be on the horizon. US motor giant Ford has expressed interest in testing Darcast cast crankshafts for its engines.

Darcast can already boast that Jaguars and Land Rovers use its crankshafts, as well as Toyota's Corolla and Avensis models, VW's Golf, Bora, Touran and Passat, and Audi's A3, A4 and A6.

"There is huge potential for our company as a result of our recent multi-million pound investment programme and the launch of our high strength material," said Mr Bransby.

"This work has secured the future of the 120 people we employ and given us a technical lead. No-one else can make cast crankshafts with the capabilities of our new high strength material and we are already looking at making further improvements to our cast iron."

The company's success last year was capped with the 2006 Company Achievement Award from The Cast Metals Federation.

By Simon Penfold