Hundreds of jobs on way as Walsall waste plant approved

Around 300 jobs will be created in Walsall after a new waste and energy plant worth up to £100 million was granted by council planning chiefs.

Up to 300,000 tons of rubbish is expected to be treated every year at the plant based on industrial land off Fryers Road, Bloxwich. Some of it would be used to generate renewable energy.

Members of the planning committee last night agreed there should be several conditions in place to ease concerns. This means there will be quarterly readings on the chimney, which will then be reported back to the council. There will also be a traffic plan of which routes should be used when making deliveries. It is expected there will be more than 80 HGVs a day arriving and departing from the site.

The plant will deal with commercial and industrial waste. A report to councillors said the scheme would 'bolster' the local economy and address a shortage of waste processing facilities in the region.

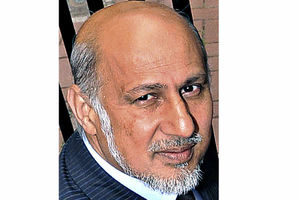

Councillor Mohammed Arif, cabinet member for environment, said: "It is not every day someone comes in to invest £100m and it is bringing in new jobs. We have always said Walsall is open to business." But Bloxwich councillor Fred Westley said he was worried about the impact on roads.

"I still have major, major concerns about the traffic," he said. "I don't think the roads surrounding the area are capable of sustaining the amount of traffic."

The scheme has been put forward by BH EnergyGap and is expected to create jobs over three years while the development is being built, alongside 50 permanent positions.

There were 11 letters of objection from residents and businesses, while concerns were also raised by councillors Tim Oliver and Shaun Fitzpatrick.

Operations are to take place in a main process building, which will include a tipping hall, waste processing hall, furnaces, boiler area flue, gas treatment area and turbine hall.

Waste is due to be collected by companies and delivered to the site where it can be weighed and delivered to a tipping hall.

Residual material will be shredded and prepared as a fuel feedstock prior to an advanced thermal treatment, called gasification, which is part of the process used to produce electricity which is then exported into the National Grid.

The facility is due to operate on a 24-hour basis, with deliveries between 7.30am and 7pm on weekdays and 7.30am to 1pm on Saturdays.