Proud history of Malthouse Engineering

Malthouse Engineering Co in Tividale has been presented with an Express & Star Excellence in Manufacturing Award. Professor Carl Chinn charts its history.

Malthouse Engineering Co in Tividale has been presented with an Express & Star Excellence in Manufacturing Award. Professor Carl Chinn charts its history.

Hubert Hands was a youngster with a mission - a mission to set up his own steel fabrication company.

Many of his deliveries were made to metal companies, including the big steel stockholding firm of Bell & Harwood in Duke Street, West Bromwich.

Upon each visit Hubert was engrossed by all that he saw, and soon found a job in manufacturing and was taken on as a foreman at Stern & Bell. There in 1936, he was saw his first Hancock flame-cutting machine.

Award - click here

It fuelled Hubert's ambitions to set up his own flame cutting and fabrications company. He confided his plans with Edgar Harwood, the key figure at Bell & Harwood where he had used to deliver groceries.

The older man was struck with Hubert's gusto - and saw an opportunity for his own business. A new venture funded by Harwood and with Hubert in charge of production would mean that the essential processes of flame-cut blanks and welded components would no longer be put out.

The Second World War forestalled this idea, but Hubert held fast to it throughout his national service. Finally demobbed in 1947. Harwood was true to his word and supplied the money for a new business. He also brought in two other investors, one of whom was William Best.

Boasting a keen business brain he was the right-hand man at Bell & Harwood and was the obvious person to take on the main management role for the emerging firm.

This was based at an old malt house in Orchard Street, Oldbury. Hubert and some of his pals cleared up the Orchard Works, including his army mate Tom Eddy, who would go on to work for the Malthouse Engineering Company Limited for more than forty years. Ronald L Christianson Ltd of Wordsley was among the first big customers. Another was Ernest Lake Ltd, a sheet-metal company. Still Bell & Harwood's was the mainstay of Malthouse, placing 38 of the first 50 orders.

In 1949 another key figure joined the company. He was Vic Westwood, who had worked at Bell & Harwood since he was sixteen. He recalled that "There were just two platers and a welder when I joined. I was to do all the office work — only me."

Filling an important niche in an economy expanding after the war, Malthouse grew rapidly and had to install new cranes, lights and roadways. Still the factory was cramped and it was increasingly difficult to keep up with the orders that were rolling in.

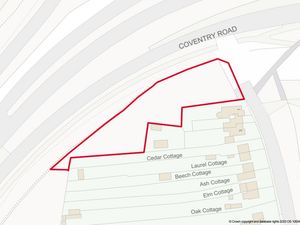

If the company were to fulfil its potential it had to move to bigger and purpose-built premises. It did so in 1952 at an industrial site on nearby Hainge Road, in Tividale.

By the mid-1960s Hubert Hands had become the main shareholder but in 1968 he sold out to Frederick Cooper Holdings Ltd — although he continued as managing director for another fifteen years.

The 1970s were plagued by economic problems, a lack of growth, rising unemployment and industrial unrest.

Like so many manufacturing concerns, Malthouse was adversely affected and in 1978 its fabrication bay was closed. With a third of the factory empty, it was vital to expand the flame-cutting business. This was achieved but trading remained tough.

Things got worse in the early 1980s when a recession and government policies devastated manufacturing in the West Midlands.

Fortunately in 1983 Roy Taylor took over as managing director. His wife, Sheila, had started work as an office junior at Malthouse in 1961 and had risen to become secretary and supervisor of the order department.

A successful engineer who had left a secure job, Roy made sure to listen in his early days at Malthouse. He emphasised to staff the need to give priority to meeting the customers' needs; while he realised that it was essential to diversify.

To this end he accepted an order for champagne-bucket stands for restaurants, mostly in London. These had four legs connected towards the base by a welded-on square piece of metal and were painted matt black. Roy Taylor improved this design. Taking the milkmaid's stool as a model he removed one leg. This saved material and welding time, and it also improved the stand's stability. Roy's son, Richard, then coated the stand with a new Hammerite powder that gave a mottled appearance hiding imperfections.

High demand for these champagne stands helped Malthouse through the tough trading of the later 1980s but it was essential that the core business also expanded. Consequently Roy reopened fabrications. Then in 1986 he led a management buyout.

A key player was Ken Webb. He had become company accountant in 1973, a position he held until his retirement in 2007. Ken and Roy formed a dynamic team. Both were dedicated to quality production and customer service, to cost effectiveness and efficiency and to investment in the future.

Since that buyout Malthouse has forged forward. It has acquired other companies; expanded its operations; gained a much larger share of UK flame-cutting market; and continuously improved production.

Today it stocks 2000 tons of plate steel - more than many of its competitors.

The Manufacturing Excellence Awards, sponsored by the Manufacturing Advisory Service in the West Midlands (MAS-WM,) has been set up to honour long-standing firms which continue a proud industrial tradition while adapting to modern times.

It couldn't be easier to enter the E&S awards - if your firm has been operating for at least 30 years and has up to 250 staff, you could be the next winner to be visited by Professor Carl Chinn.

Email newsdesk@expressandstar.co.uk or write to Carl Chinn, Express & Star Manufacturing Awards, c/o The Editor, Express & Star, Queen Street, Wolverhampton, WV1 1ES.