Willenhall steel giant backs site with £2.6m investment

The world's biggest steel company has pumped nearly £2.6 million into modernising its processing site in Willenhall, equipping it with a machine used to make parts for the Large Hadron Collider in Switzerland, the particle accelerator that discovered the so-called God Particle.

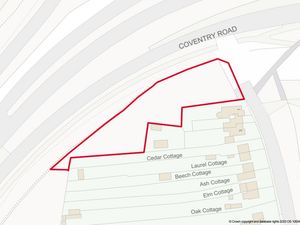

Upgrading the slitting and blanking lines at the ArcelorMittal site in Strawberry Lane means the plant will be able to process up to 200,000 tons of steel a year with three machines.

This is a dramatic increase on its previous productivity with six machines.

Regional head of sales for ArcelorMittal Distribution Solutions, Neil Harvey, said that by taking ageing machinery out of the site, it would clear space to be able to hold a wider range of stock and improve the turnaround of orders.

"Out customers need a rapid response, and by holding a more optimised range of stock as standard and operating faster processing machinery we will be able to give them what they need in just 24-48 hours," he said.

"By increasing our productivity we are investing for the future on this site, so we can cater for the increase in manufacturing that we believe will come in the Midlands and the wider UK.

"Many of our customers at the moment are in the immediate West Midlands area but we are confident this investment will attract clients from much further afield."

The investment also helps secure the future of the 53 staff working at the 16,000 sq m processing centre. The faster and more modern machinery will mean the site can offer precision cut blanks from just 0.4mm thick up to 8mm thickness as well as stocking standards sheets up to 20mm.

The investment programme has also added a second stacker to the site's Georg blanking line, so it can process more steel more quickly.

This was last used in Belgium to produce the 50,000 tons of magnetic steel used to build the Large Hadron Collider. At Willenhall it is able to replace three old processing lines.

In its new home, the equipment will process steel for parts supplied to 'yellow goods' manufacturers - construction and mining equipment makers - lorry trailer manufacturers, metal office furniture companies and motorway crash barrier companies such as Hill & Smith based in nearby Bilston.

As part of a global business with sites around the world - including two nearby in Rowley Regis and Halesowen – the Strawberry Lane team had to come up with a persuasive case for the investment.

ArcelorMittal's distribution chief executive in the UK, Sven Van de Putte, said: "The investment will help us cater to demand, reduce lead times for our customers and broaden our capabilities from this site. It also makes us much more flexible.

"Our new equipment means we can double output from this site, which can operate 24 hours a day."